News

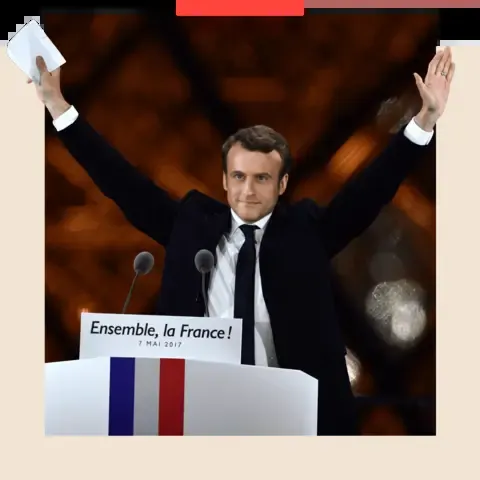

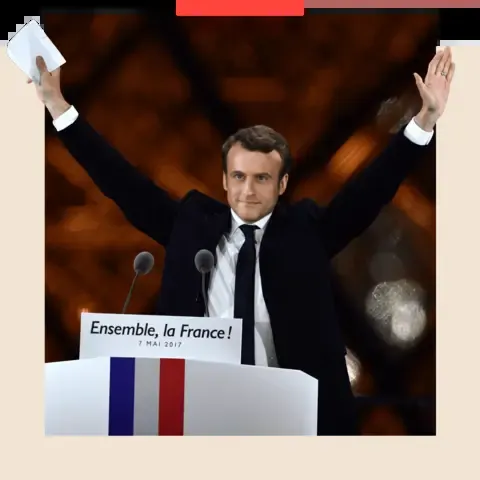

The Reasons The French Nation Faces Becoming Europe’s Latest Struggling Power of Europe

Discover amazing stories and insights from our featured article.

Discover amazing stories and insights from our featured article.

Explore the intersection of technology and creativity through storytelling in the digital era.